·

Marshall is one of the most influential and historic amp manufacturers in the world. As leader of the Amplification Project, as soon as I learned that the company has a dedicated education department, I reached out to set up an appointment to visit the main factory in Bletchley with several members of my research team.

The Marshall factory has its own on-site museum dedicated to the history of the company’s products. Because of Marshall’s significance, there are several books that document its history and recount the life of founder and namesake Jim Marshall. After reading everything I could get my hands on about the company, the museum provided a unique opportunity to see many of the most pivotal Marshall amps up close. Many of the amps on display are notable for having been played by iconic musicians. There are amps that were played by Slash, Lemmy from Motörhead, Zakk Wilde, Paul Weller, and the infamous Spinal Tap “goes to 11” amp, as well as models of the amps that have been played by Jimi Hendrix, Pete Townshend, Ritchie Blackmore, and a host of other rock luminaries. In the middle of it all was the very first amp every built by Marshall, which is now behind a glass display case, enshrining the moment when Jim Marshall and his collaborators first made the move from running a music retail store to becoming the manufacturer of amps that would be the first choice for multiple generations of performing artists.

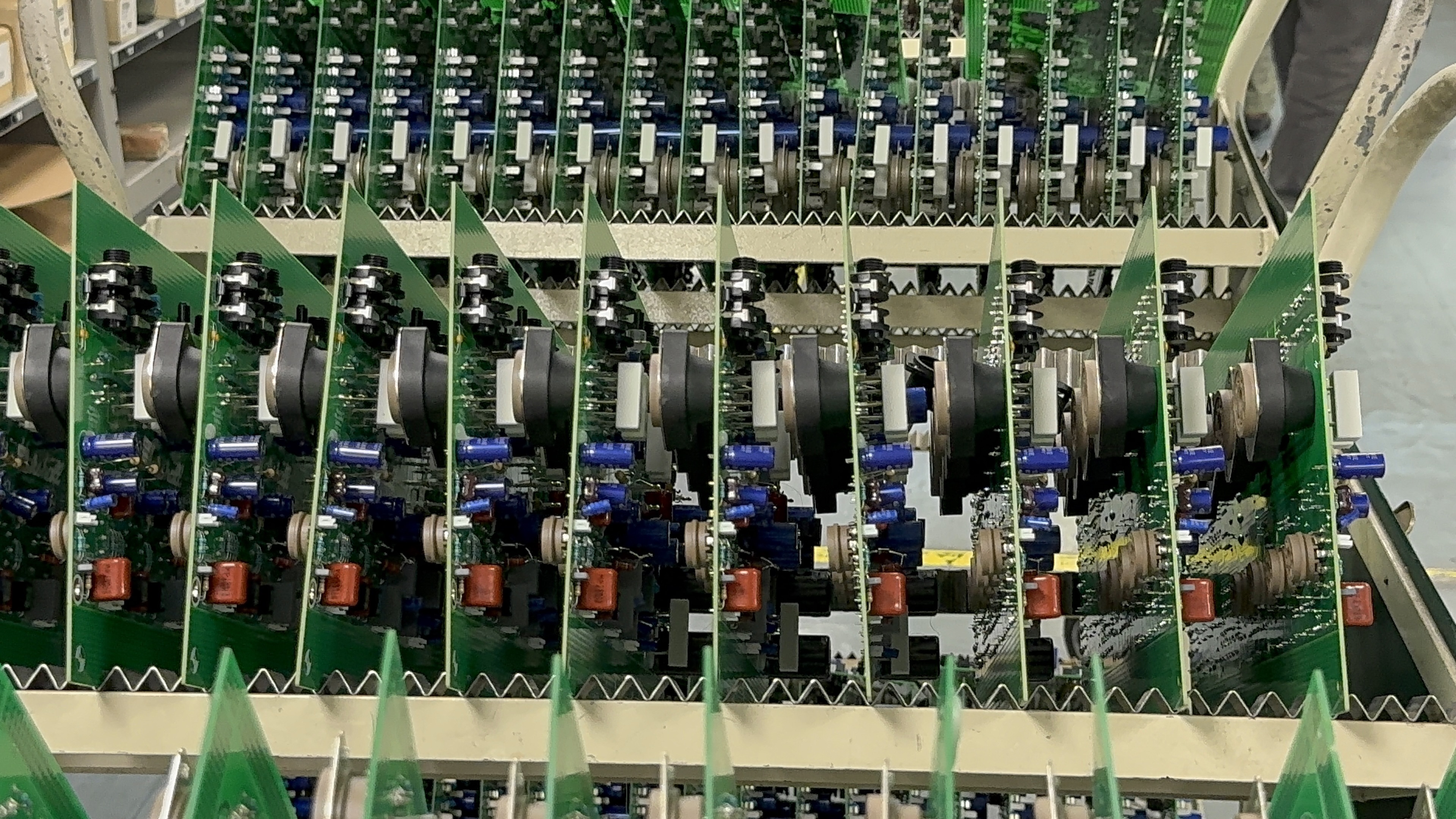

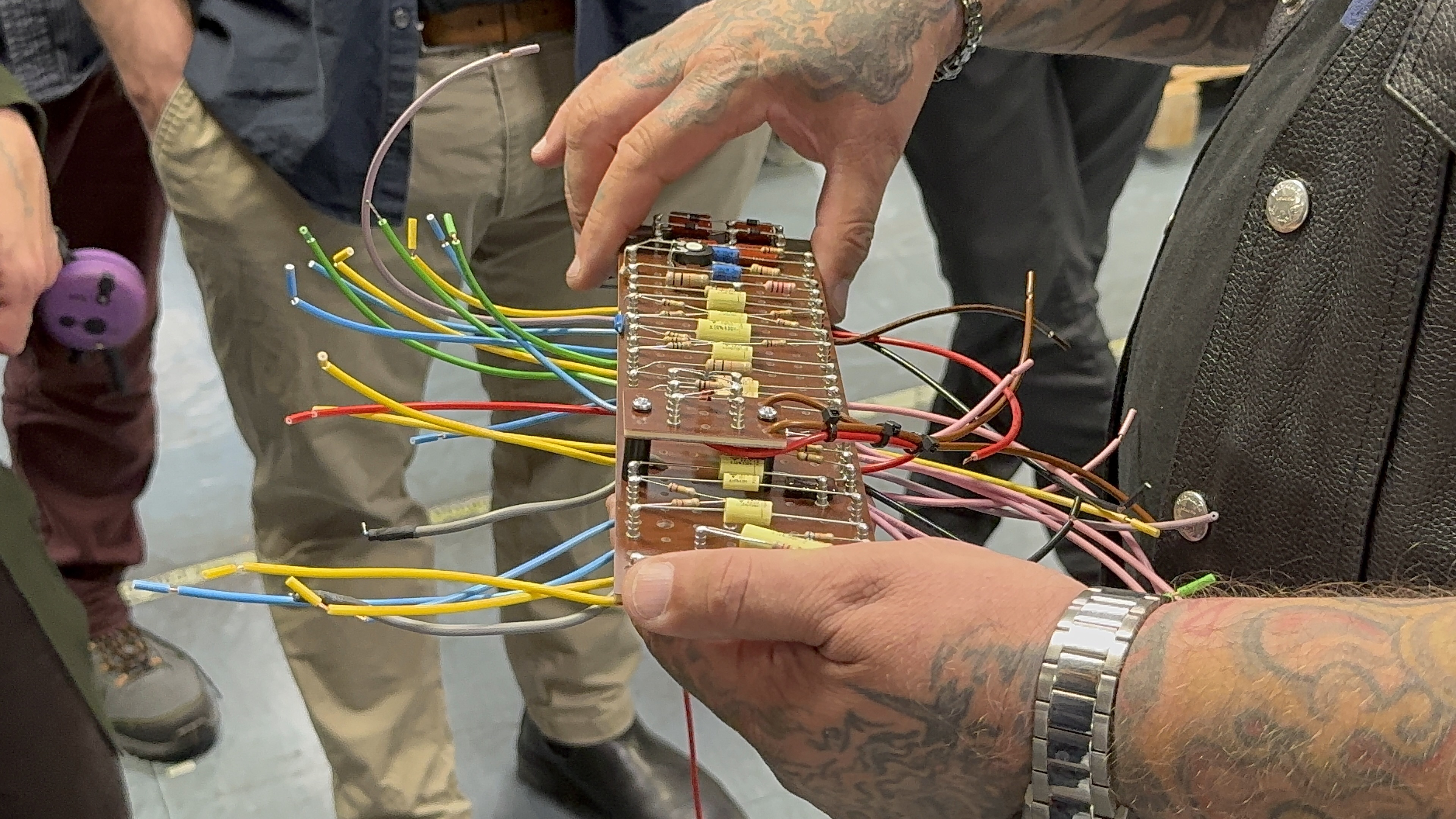

As eye-opening as the museum was, the real excitement came with the factory tour. We spent over an hour walking through the working Marshall factory in the middle of an ordinary workday for the company’s employees. Our tour guide, Steve – himself a 40-year employee with the company – led us through the various stages of the Marshall production process. We saw circuit boards being soldered together by a dedicated machine, while in a nearby workstation a different set of circuit boards were being hand wired by highly skilled craftspeople. In other rooms of the factory, we saw cabinets being carved and assembled, being covered in tolex (the cratered vinyl that gives the amps their unique appearance), and saw the chassis with all the requisite components being put together and installed. Throughout, we also got glimpses into the distinctive corporate culture of Marshall as well – signs that encouraged workers to “make it loud,” or said jokingly, “Danger: Guitar will not work properly without Marshall.”

While we were kept at a safe distance from the machinery, we came away with a vivid sense of the complex mix of automated processes and finely honed handiwork that goes into the making of Marshall’s amps. As our project evolves, I hope that we can use this knowledge as a building block to gain greater levels of insight into how amps are made and designed and what features contribute to the distinctive tonal properties that they possess.